A robot is generally defined as a programmable machine capable of carrying out a series of actions automatically. Unlike simple machines, robots can be reprogrammed to perform different tasks and often operate with a degree of autonomy or responsiveness to their environment. The classic industry definition from the Robot Institute of America (1979) describes a robot as “a reprogrammable, multifunctional manipulator designed to move material, parts, tools, or specialized devices through various programmed motions for the performance of a variety of tasks.” In practical terms, this means a robotic system can be instructed to do many different things (multifunctional) and can be reconfigured without physical alteration (reprogrammable). Modern standards, such as the International Organization for Standardization’s ISO 8373, similarly define an industrial robot as an “automatically controlled, reprogrammable multipurpose manipulator, programmable in three or more axes”. These definitions emphasize that robots combine mechanical components with computer control to perform work typically done by humans or to execute tasks in automated ways.

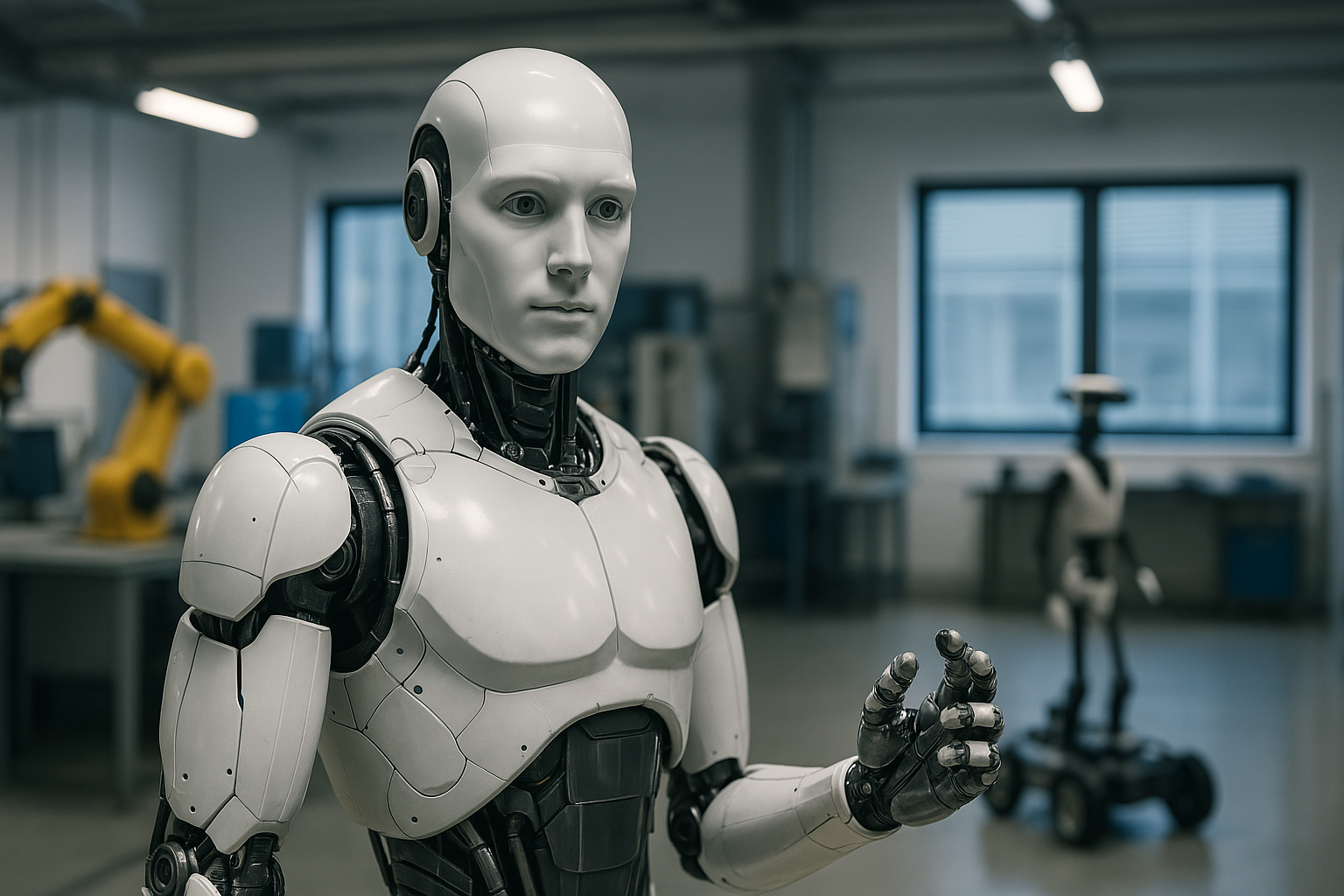

Robots vary widely in form and function, but most share some key characteristics. They usually have the ability to sense their surroundings (through sensors like cameras, infrared, touch, etc.), to process information (via onboard computers or AI algorithms), and to actuate movement or operations (through motors, servos, or other actuators). This sense-compute-act loop allows robots to respond to changing conditions within pre-defined limits. Some robots are stationary, like robotic arms bolted to a factory floor, while others are mobile, moving through the world. Some are even designed to resemble living creatures or humans, whereas others are purely functional in appearance. Importantly, a machine doesn’t need to look humanoid to qualify as a robot; industrial robotics focuses on task efficiency, and many robots appear as mechanical arms or boxy vehicles. In everyday language, the term “robot” can also extend to software agents (like web crawlers or “bots”), but in a strict sense – especially within robotics research – it usually denotes a tangible electro-mechanical system. Indeed, the International Federation of Robotics notes that there is “no single agreed definition of a robot” in all contexts, but most agree it involves a physical machine that operates autonomously to some degree to accomplish tasks.

Etymology: The word robot itself entered the modern lexicon through literature. It was first used in the 1920 science-fiction play R.U.R. (Rossum’s Universal Robots) by Czech playwright Karel Čapek. Čapek borrowed the term from the Czech word “robota,” which means forced labor or drudgery, especially the kind of serf labor common in feudal systems. In the play, Čapek’s “robots” were mass-produced artificial factory workers – more akin to what we might now call androids – who eventually revolted against their human creators. The term resonated and was soon adopted into numerous languages to describe automated servants or machines. A couple of decades later, Russian-American science fiction writer Isaac Asimov coined the word “robotics” to describe the field of study related to robots. Asimov introduced robotics in his 1942 short story “Runaround,” in which he also proposed the now-famous Three Laws of Robotics as fictional ethical guidelines for robot behavior. Thus, from its very origin, the concept of “robot” has been intertwined with both the promise of mechanized labor and the accompanying social and ethical implications.

History of Robotics

Ancient Automata: The idea of creating autonomous machines or automata extends deep into ancient history. As early as ~3000 B.C., Egyptian engineers built water clocks featuring human figurines that struck the hour bell automatically. Classical Greek myths told of mechanical servants built by the god Hephaestus, and around 400 B.C. the philosopher Archytas of Tarentum reputedly constructed a steam-propelled wooden bird – an early example of a self-moving device. In the Hellenistic period, Hero of Alexandria wrote treatises describing self-operating machines, and by the Middle Ages and Renaissance, European artisans were crafting intricate clockwork automatons. For example, 18th-century European watchmakers designed moving figurines (automated ducks, dolls, musicians, etc.) that amazed audiences. These devices were precursors to robots, demonstrating humanity’s longstanding fascination with imitating life through machinery. However, these early automata were fixed sequences of mechanical actions – they could not sense or adapt to changes – distinguishing them from true modern robots that incorporate sensors and control systems.

Origin of the Term: The modern concept of a “robot” as we understand it began to crystallize in the early 20th century. Karel Čapek’s 1921 play R.U.R. introduced the term robot into popular culture. In Čapek’s play, the robots were artificial biological beings made to perform work, and the drama explored themes of industrial dehumanization and rebellion. The choice of the word robota (forced labor) highlighted that these artificial workers were effectively slaves, created to toil on behalf of humans. The play struck a chord in an era of rapid industrialization, and by the late 1920s and 1930s, the word “robot” was being used beyond literary contexts to describe real mechanized systems and imaginary future machines. Early usage blurred the line between humanoid machines and any labor-saving automatons.

In 1942, Isaac Asimov not only gave the field its name robotics but also imagined guiding principles for robot behavior. Asimov’s Three Laws of Robotics were formulated as: (1) A robot may not harm a human being or, through inaction, allow a human to come to harm; (2) A robot must obey human orders unless those orders conflict with the First Law; (3) A robot must protect its own existence as long as such protection does not conflict with the first two laws. These laws (later augmented by Asimov with a “zeroth” law about not harming humanity as a whole) were fictional, yet they became enormously influential in shaping public expectations about robot behavior and ethics. Mid-20th-century scientists were inspired by such ideas even as they began building the first real robots. Ironically, the very term Asimov coined – robotics – anticipated the emergence of an engineering discipline that did not yet fully exist when he wrote the stories.

First Modern Robots: The 1950s saw the advent of devices widely considered the first modern robots. American inventor George C. Devol created a reprogrammable mechanical arm in 1954 that he called “Unimate.” Devol’s invention was a turning point: unlike fixed automation machines, his robotic arm could be programmed to carry out different step-by-step tasks without rebuilding the machinery. After receiving a U.S. patent for this reprogrammable manipulator in 1961, Devol teamed up with entrepreneur Joseph Engelberger to commercialize the technology. Engelberger founded Unimation, the world’s first robotics company, in 1956–1962 to manufacture Unimate and promote its use in industry. In 1961, the Unimate robot was installed on a General Motors assembly line in New Jersey – the first industrial robot to work in a factory. This robotic arm repetitively lifted and stacked hot pieces of die-cast metal, automating a dangerous task that had been done by humans. The success was modest at first (GM paid a hefty price for a machine that essentially moved castings), but it proved the concept. Engelberger, often called “the father of robotics,” evangelized the potential of robots to revolutionize manufacturing. Throughout the 1960s, Unimation improved the robot’s design and more companies and factories began to take interest in automation.

Around the same time, research institutions were pushing the boundaries of what robots could do beyond the factory floor. In 1966, Stanford Research Institute (SRI) developed a robot named Shakey – famously regarded as the first mobile robot that could perceive and make decisions about its environment. Shakey was a wheeled platform equipped with a camera and bump sensors, connected to a computer. By 1970, it was able to navigate modest indoor environments, avoid obstacles, and even plan simple actions like pushing blocks around based on commands – a primitive early example of robot autonomy and AI integration. Although Shakey moved very slowly and clumsily (earning its name from its trembly motion), it demonstrated visionary concepts: mapping surroundings, reasoning about goals, and acting in the physical world. This was robotics merging with artificial intelligence research, laying groundwork for future mobile and service robots.

Industrial Boom: By the 1970s, industrial robots began proliferating in manufacturing settings. Companies in Japan, Europe, and the U.S. developed their own robotic arm models for tasks such as welding, painting, and assembly in automotive production. Notably, Japanese firms (like FANUC and Kawasaki) licensed early designs from Unimation and by the late 1970s had made significant advancements, contributing to Japan’s manufacturing boom in the 1980s. During this era, robotics as a field solidified: academic programs and research labs dedicated to robotics were established, and conferences and journals appeared. Engineers developed new types of mechanical structures – for example, the SCARA robot (Selective Compliance Assembly Robot Arm) was invented in 1981 in Japan for fast pick-and-place tasks in electronics assembly, while others built robot arms with higher precision or heavier payload capacities. The term “robotics” now referred to a broad industry and scientific discipline encompassing mechanical design, control systems, electronics, and computer science.

By 1980, according to historical records, there were already thousands of industrial robots working in factories worldwide. General Motors had dozens of Unimates and other robots in operation, and other car makers followed suit. In 1987, the International Federation of Robotics (IFR) was founded as an industry body to track and promote robotics growth. The IFR began publishing World Robotics reports, documenting the rapid increase in robot installations. For example, robot use in automotive plants became standard for tasks like spot welding and spray painting due to the quality and efficiency benefits. These decades also saw robotics expanding into structured environments beyond manufacturing: robotic arms were used in laboratories for sample handling, and primitive mobile robots were used in warehouses for simple transport tasks. Still, outside of industry and research, robots had not yet entered daily life.

Robots in Popular Imagination: The cultural impact of robots grew in the late 20th century through film and media, even as real robots were mostly industrial. The 1960s and 1970s witnessed iconic fictional robots (from Robbie in Forbidden Planet to R2-D2 and C-3PO in Star Wars), which shaped how the public perceived robots – often as human-like companions or helpers. This popular imagery sometimes clashed with reality; industrial robots were essentially computer-controlled mechanical arms behind safety fences, far from the anthropomorphic machines of fiction. Yet, by the 1980s and 1990s, robotics research had produced actual prototypes of humanoid or animal-like robots (e.g. bipedal walking machines in labs, or range of wheeled service-robot prototypes), foreshadowing what was to come.

Late 20th and Early 21st Century: In the 1990s, robotics began entering more varied domains. Notably, space exploration became an exciting frontier for advanced robots. NASA had long used automated spacecraft and planetary probes, but in 1997 it landed Sojourner on Mars – a small six-wheeled rover that became the first robot to roam another planet. Sojourner’s successful three-month mission demonstrated that robots could extend humanity’s reach to hazardous and distant environments, acting as our explorers. This opened the door for larger Mars rovers in the 2000s (Spirit, Opportunity, Curiosity, and Perseverance), each essentially robotic geologists on Mars. Back on Earth, the late 1990s saw robots inch into the consumer realm: in 1996, Pathfinder by iRobot was a prototype of an indoor mobile robot, and by 2002 the first popular home robot, the Roomba vacuum cleaner, was introduced, autonomously cleaning floors in people’s houses.

Humanoid and Mobile Robots: A milestone in robotics was achieved in 2000 when Honda unveiled ASIMO, a human-shaped bipedal robot. ASIMO could walk, climb stairs, and interact with people, showcasing remarkable advances in balance and motion control for humanoid robots. Throughout the 2000s and 2010s, humanoid robots remained an active research area – companies and labs worked on robots like Toyota’s Partner robots, Pal Robotics’ REEM, and the publicly demonstrated Atlas humanoid from Boston Dynamics (initially developed for DARPA, the U.S. Defense Advanced Research Projects Agency). These machines progressively mastered walking on uneven terrain, lifting objects, and in dramatic demonstrations, even jumping and doing gymnastics. In 2017, Boston Dynamics famously released a video of its Atlas robot performing a backflip, an achievement highlighting how far locomotion and dynamic control had come. Although humanoid robots are still not common in daily life, these research breakthroughs have “profound implications for what robots might be able to do in the future” in roles like disaster response or construction.

Mobile robotics also advanced rapidly with the rise of better sensors (like laser scanners and depth cameras) and computing. By the 2010s, robots were navigating hospital corridors to deliver supplies, moving through warehouses to fetch products (Amazon’s acquisition of Kiva Systems in 2012 led to thousands of warehouse robots scurrying under shelves), and even driving on public roads as experimental self-driving cars. Autonomous vehicles, essentially robots on wheels, went from a DARPA Grand Challenge curiosity in 2004 to real test fleets by companies like Google/Waymo, Tesla, and others by the late 2010s. In the air, unmanned aerial vehicles (drones) became widespread; while early drones were remote-controlled, increasingly they gained autonomous flight capabilities, effectively functioning as flying robots for surveillance, mapping, or photography.

Contemporary Status: Entering the 2020s, robotics is a mature but fast-evolving field. Robots have dramatically increased in number and capability. In manufacturing alone, the global stock of operational industrial robots hit a record high – by 2023, more than 4 million industrial robots were working in factories worldwide. These range from large automotive welding robots to small collaborative arms used in electronics assembly. Service robots – from autonomous vacuum cleaners to medical robots – have also multiplied in sectors like healthcare, logistics, retail, and defense. The progress in artificial intelligence, particularly machine learning and computer vision, has enabled robots to perform ever more complex and adaptive tasks. For instance, modern robots can recognize objects and people, make on-the-fly decisions in unstructured environments, and learn some behaviors from experience. The history of robots thus spans ancient dreams of mechanical beings to the sophisticated automation of today’s industries and the increasingly intelligent machines moving among us. Each era’s developments build on the last, and the pace of innovation in robotics continues to accelerate.

Types of Robots

Robots can be classified in several ways, such as by their form factor, their application area, or their level of autonomy. Below are some of the major categories and types of robots:

- Industrial Robots: These are robots used in manufacturing and industrial environments. Typically, an industrial robot is a robotic arm (or a multi-jointed mechanism) that is fixed in place or sometimes mounted on a mobile platform within a factory. Industrial robots are designed to perform tasks like assembly, welding, painting, material handling, and packaging with high speed and precision. According to the ISO 8373 standard, an industrial robot is an “automatically controlled, reprogrammable multipurpose manipulator … for use in industrial automation applications.” Most industrial robots have a series of joints (either rotational or linear) giving them several degrees of freedom to position a tool or gripper in 3D space. Common configurations include the six-axis articulated robot arm, SCARA robots (used for pick-and-place tasks), delta robots (with three arms for extremely fast picking motions), and cartesian/gantry robots (which move along linear X-Y-Z axes). Industrial robots often operate in structured settings like assembly lines, where they repeatedly execute programmed motions. They tend to be physically large and powerful – for example, a robotic arm in an auto plant can weigh several tons – and thus are typically kept segregated from human workers for safety (though this is changing with collaborative robots, discussed below). Industrial robots have become a backbone of high-volume manufacturing, improving productivity and quality in production. By taking over dangerous or repetitive “dull, dirty, and dangerous” tasks like 24/7 welding or handling toxic materials, these robots also improve workplace safety. Modern developments in this category include collaborative robots (cobots) which are industrial-grade arms with added safety features (sensors, force limits) that allow them to work alongside humans without fencing.

- Service Robots: Service robots are those designed to assist humans in non-industrial tasks, often in everyday environments. The International Federation of Robotics broadly defines a service robot as a robot that “performs useful tasks for humans or equipment excluding industrial automation applications.” This category is extremely broad, encompassing any robot outside the factory setting. Service robots can further be divided into professional service robots – used in commercial or institutional settings by trained operators – and personal service robots – used by the general public, often in home environments. Examples of professional service robots include medical robots (like surgical robots in hospitals, or rehabilitation robots in clinics), logistics robots (autonomous guided vehicles in warehouses, delivery robots in offices), agriculture robots (automated tractors or robotic harvesters), and public safety robots (bomb-disposal robots used by police, or inspection robots for infrastructure). Personal service robots include things like domestic cleaning robots (robot vacuum cleaners and lawn mowers), personal mobility or assistance robots (robotic wheelchairs, exoskeletons for mobility impaired persons), and entertainment or educational robots (toy robots, tutoring robots). The key distinction from industrial robots is that service robots operate in more dynamic, human-centric environments and handle a variety of tasks aimed at directly serving people. They may navigate through homes or crowds, interact with users, or handle objects that are not presented in fixed positions. As such, service robots often incorporate sophisticated sensors (cameras, LiDAR, etc.) and AI to perceive their environment. For instance, a hospital delivery robot must navigate hallways, call elevators, avoid people, and securely transport medicine; a robotic exoskeleton must synchronize with a human’s movements in real-time to provide support. Many service robots are mobile, which overlaps with the next category of mobile robots.

- Mobile Robots: This class of robots is defined by the ability to move through their environment (rather than being anchored in one spot). Mobile robots can use wheels, legs, tracks, or even airborne motion (drones) to travel. They are crucial for tasks that require navigation of the real world. Mobile robots can further be specialized into sub-types:

- Wheeled Robots: The most common mobile platforms use wheels or tracks (like a tank) to move on relatively flat surfaces. Examples include warehouse robots that carry shelves, indoor security robots that patrol buildings, or research robots that traverse rough outdoor terrain on wheels. Wheeled robots benefit from simplicity and efficiency on smooth terrain.

- Legged Robots: These robots use articulated legs to walk, imitating animals or humans. Bipedal (two-legged) robots like humanoids fall here, as do quadrupedal robots (four-legged) like Boston Dynamics’ Spot robot dog. Legged locomotion is more complex but allows navigation of complex terrains (steps, obstacles) that wheels might struggle with. Recent strides in control and balance have made legged robots increasingly practical for applications like disaster-site exploration or carrying payloads over uneven ground.

- Drones / Aerial Robots: Often not immediately thought of as “robots,” unmanned aerial vehicles (UAVs) are indeed robotic systems. Autonomous drones can fly without continuous human control, using onboard stabilization and navigation algorithms to perform tasks like aerial photography, agricultural monitoring, or search-and-rescue reconnaissance. They use rotors (quadcopters and similar) or fixed wings for flight. Aerial robots have unique freedom of movement in 3D but must contend with weight and battery constraints.

- Underwater Robots: Also known as autonomous underwater vehicles (AUVs) or remotely operated vehicles (ROVs) if tethered, these robots are designed for aquatic environments. They inspect ship hulls, survey coral reefs, or explore deep ocean geology. Moving underwater presents challenges of communication (since radio waves don’t travel far in water) and pressure, so many underwater robots are pre-programmed to perform missions with limited realtime control from operators.

- Self-Driving Vehicles: A special case of mobile robots are autonomous cars, trucks, and other vehicles. They use a suite of sensors (cameras, radar, LiDAR) and AI to perceive traffic and make driving decisions. Autonomous vehicles are essentially robots that share the road with human drivers. Numerous companies are developing self-driving taxis, freight trucks, and even autonomous delivery robots that drive on sidewalks or roads to bring goods to customers.

Mobile robots often use simultaneous localization and mapping (SLAM) techniques to build a map of their environment and navigate within it. With improved batteries and motors, many mobile robots can operate for hours and carry significant payloads. Autonomy levels vary: some mobile robots are fully autonomous, while others might be teleoperated by humans or work in a semi-autonomous mode (handling movement while a person supervises high-level tasks).

- Humanoid and Social Robots: Humanoid robots are robots constructed to resemble the human body shape (with torso, two legs, two arms, head, etc.). The goal of humanoids is often to achieve mobility and manipulation capabilities similar to a person and to operate tools or environments built for humans. Beyond Honda’s ASIMO, other examples include HUBO (KAIST, Korea), Atlas (Boston Dynamics, US), and Toyota’s T-HR3. Humanoids are often used in research to study bipedal locomotion, balance, and human-robot interaction. Some humanoid robots also serve as social robots, meaning they interact with people in a human-like social way (speaking, gesturing) to provide information or companionship. For instance, Pepper by SoftBank Robotics is a human-shaped robot designed to greet people in stores, answer questions, or converse – essentially a robot receptionist. Similarly, NAO (by Aldebaran/SoftBank) is a small humanoid used in education and research on social interaction. These robots have expressive features (like eyes that light up or arms that gesture) and use speech recognition and generation to communicate. Social robots need not be fully humanoid; some are animal-like (e.g., Paro the robotic seal used in therapy). What defines them is the focus on engaging with humans on a social or emotional level. Humanoid and social robots are still emerging technologies – they tend to be relatively expensive and limited in capability – but they represent an effort to integrate robots more seamlessly into human environments and routines.

- Specialized Robots: There are many other specialized robot categories targeting particular tasks or industries:

- Medical Robots: These include surgical robots such as the da Vinci Surgical System, which is a teleoperated robotic platform that allows surgeons to perform minimally invasive surgery with enhanced precision. Surgical robots translate the surgeon’s hand movements into finer, tremor-filtered instrument motions inside the patient. Other medical robots are designed for rehabilitation (helping patients perform exercises, e.g., robotic exoskeletons for gait training) or for prosthetics (robotic prosthetic limbs that respond to muscle signals). There are also micro/nanorobots in experimental stages for targeted drug delivery in the body.

- Exoskeletons: A type of wearable robot that a human can strap onto their body. Exoskeletons provide powered assistance to limbs, augmenting strength or endurance. They have applications in physical rehabilitation (helping a patient walk or regain limb movement) and in industry (enabling workers to lift heavy objects with less strain). Essentially, exoskeletons are mechanical frameworks with motors that mirror and amplify the user’s movements.

- Military and Security Robots: Beyond aerial drones, militaries employ ground robots like the PackBot or TALON for reconnaissance, bomb disposal, or handling hazardous materials. These tend to be tracked or wheeled devices, often remote-controlled but increasingly with autonomous navigation features. Security robots, used for surveillance of property or border patrol, also fit here – for example, small autonomous robots that roam businesses at night scanning for intruders or fire.

- Exploration and Field Robots: Robots designed to operate in harsh or remote environments such as planetary rovers (Mars rovers), deep sea explorers, volcanic exploration robots, or polar research robots. Their focus is on resilient hardware and autonomous operation where direct human control is difficult.

- Microrobots and Swarm Robots: At the cutting edge of research, there are robots at very small scales (millimeter or sub-millimeter), which could work in swarms to collectively perform tasks – for instance, swarms of tiny robots might collaborate to sense environmental conditions or assemble into larger structures. This is an emerging area with potential future applications in fields ranging from environmental monitoring to medicine.

It’s important to note that these categories can overlap. For example, a humanoid robot is also a mobile robot and could be considered a service robot if it’s used in a public setting. Conversely, an industrial robot might be mounted on a mobile platform (blurring the line between industrial and mobile categories). Collaborative robots (cobots), which are designed to work directly with humans, can be seen as a sub-type that spans industrial and service domains, since they may be in factories or even in home workshops assisting people.

The taxonomy of robots is evolving as new designs emerge. Nonetheless, whether it’s a factory arm boosting production or a friendly home assistant on wheels, all robots share the core trait of an embodied artificial agent that can sense, decide, and act in the physical world to carry out tasks.

Applications of Robots

Robots are employed across a vast array of industries and activities. Initially, their primary use was in manufacturing, but today they appear in sectors as diverse as medicine, agriculture, logistics, and even hospitality. Below are some of the major application domains for robots, along with how robots are utilized in each:

- Manufacturing and Assembly: This remains one of the largest domains for robotics. Industrial robots on assembly lines weld car frames, assemble electronic devices, rivet airplane parts, and perform hundreds of other production tasks with speed and accuracy. In automobile manufacturing, for example, robotic arms handle everything from welding the chassis to painting the car’s exterior. Robots excel in such tasks due to their repeatability and strength – they can work nonstop without fatigue, achieving precision that improves product quality. They have also enabled mass customization in manufacturing by being quickly reprogrammed for new models or tasks. Beyond automotive, industries like consumer electronics rely heavily on robots for assembling small components and for packaging. Robots also help with quality inspection using machine vision systems to detect defects. The end result is higher productivity and lower production costs. Modern factories increasingly incorporate not just isolated robotic arms but whole robotic workcells or production lines with multiple robots sequentially building a product. According to industry reports, annual shipments of industrial robots have been in the range of 400,000–500,000 units in recent years – a testament to their indispensability in manufacturing.

- Logistics and Warehouse Automation: With the rise of e-commerce and the need for efficient supply chains, robots have become vital in warehouses and distribution centers. Mobile robots carry shelves of products to human pickers (as in Amazon’s fulfillment centers that use Kiva robots) or directly retrieve and sort goods for shipping. Automated guided vehicles (AGVs) or autonomous mobile robots ferry materials across factory floors and warehouses, often navigating using lasers or markers. There are robotic sortation systems in postal and courier facilities that can automatically route parcels by zip code. Automated storage and retrieval systems (AS/RS) use crane-like robots to store and retrieve items in large warehouses with high racks, maximizing use of space and speed. These logistic robots improve throughput and reduce the need for manual labor in jobs that involve constant walking or forklift driving. In ports, robotic container handlers and automated straddle carriers move shipping containers. In retail, some stores use inventory robots that roam aisles, scanning shelves for stock levels or pricing errors. The overall effect is a more efficient supply chain – orders can be processed faster and more reliably with robotic assistance.

- Healthcare and Medicine: Robots are increasingly common in the medical field. One of the most prominent examples is the surgical robot. Systems like the Da Vinci allow surgeons to perform delicate operations through tiny incisions (laparoscopic surgery) by controlling robotic instruments. The robot’s precision filters out hand tremors and allows maneuvers that human wrists cannot easily perform, resulting in minimally invasive surgeries with smaller incisions, less blood loss, and faster patient recovery. Surgical robots have been used in procedures such as prostate surgeries, cardiac valve repairs, and kidney surgeries. Beyond surgery, rehabilitation robots help patients regain movement – for example, robotic exoskeletal suits can assist paraplegics in walking a few steps, and robotic arms may help stroke patients execute repetitive movement exercises. Prosthetics have also entered a robotic age: advanced prosthetic limbs now incorporate robotic joints and microprocessors, allowing hand prostheses that can grasp objects in coordinated ways when the user triggers them via muscle signals. In hospitals, telepresence robots (essentially mobile video-conferencing units) allow doctors to remotely visit patients, and specialized robotic systems can assist nurses by carrying loads (medicine delivery robots) or even performing disinfection (UV-light emitting robots that sterilize rooms autonomously). In pharmacies, robotic dispensers count and prepare medications. Overall, robots in healthcare aim to improve precision in treatment, reduce invasiveness, and alleviate the physical workloads on medical staff.

- Exploration and Space: Ever since the Apollo astronauts left a “lunar rover” on the Moon, robots have been integral to space exploration. Planetary rovers are essentially robotic geologists on other worlds. NASA’s Mars rover missions – from the small Sojourner in 1997 to the car-sized Perseverance rover in 2021 – demonstrate robots’ unique ability to operate where humans cannot easily go. These rovers travel across the Martian surface, take photographs, analyze soil and rocks with onboard laboratories, and even collect samples (Perseverance is caching samples for future return). They function with a high degree of autonomy due to communication delays; for example, they can navigate around obstacles on their own. In Earth orbit, robotics has enabled construction and servicing of space infrastructures: the Canadarm robotic arms on the Space Shuttle and International Space Station (ISS) have been used to deploy satellites, assist astronauts on spacewalks, and even remotely perform maintenance tasks on the ISS. A specialized robot on the ISS, Dextre, can perform fine manipulation tasks like changing experimental modules, reducing the need for risky astronaut EVAs. Underwater, exploration robots (like Jacques Cousteau’s concepts turned reality) and autonomous submersibles explore the ocean depths, mapping the seabed or studying marine life where human divers cannot reach. In all these cases, robots extend our senses and work into environments that are too dangerous, remote, or inaccessible for direct human presence.

- Military and Security: Military organizations around the world employ robots for tasks that would put soldiers in harm’s way. A well-established example is the use of bomb-disposal robots by bomb squads. These remotely operated tracked robots can inspect suspicious packages or roadside bombs (IEDs) and neutralize them with disruptors, keeping humans at a safe distance. On the battlefield, ground robots such as small unmanned ground vehicles (UGVs) scout ahead of troops to detect ambushes or hazardous materials. Aerial drones are widely used for reconnaissance and surveillance, and larger armed drones have been used in combat roles. There is active research into autonomous military vehicles and robotic combat agents, although the deployment of fully autonomous lethal robots raises significant ethical debate (see Ethics section). For domestic security, robots are used in roles like perimeter patrol – some security firms have robots that autonomously patrol warehouses or parking lots, equipped with cameras and sensors to detect intruders or anomalies. Some police forces use telepresence robots for hostage situations (to negotiate or gather intel). At border security, experimental robot scouts or surveillance towers use AI to monitor large areas. Robots in these applications aim to enhance situational awareness, remove humans from immediate danger, and provide capabilities like persistent surveillance that would be difficult for people to manage.

- Home and Daily Life: In the personal sphere, robots are making inroads into daily life, primarily through simple labor-saving gadgets. The most successful class so far has been domestic cleaning robots. Robotic vacuum cleaners (like the Roomba) autonomously roam home floors, detecting obstacles and dirt, and keeping homes tidy with minimal human intervention. Robotic pool cleaners and lawn-mowing robots operate on similar principles, handling mundane chores for homeowners. Personal assistant robots are an emerging category – ranging from Alexa-type smart speakers on wheels that can follow you and act as a secretary, to companion robots like Sony’s Aibo robotic dog which provides entertainment and emotional companionship. Although still rudimentary, such companion robots are used in some eldercare settings, where a cute interactive robot pet can have therapeutic effects, reducing loneliness among seniors. Kitchen robots are also under development: prototype robot arms can be installed in a kitchen to chop ingredients and even cook complete recipes, though these are not yet common consumer products. As smart homes advance, appliances are increasingly robotically capable (for instance, robotic window cleaners that climb glass surfaces). While the average household might not yet have a humanoid butler, incremental robotic solutions are steadily addressing specific domestic tasks.

- Hospitality and Customer Service: A novel but growing application is robots that interact with customers in service industries. Some hotels and shopping malls experiment with receptionist or concierge robots – humanoid or kiosk-like robots that greet visitors, provide information, or even escort guests to locations. In Japan, banks and malls have deployed SoftBank’s Pepper robot to answer basic customer queries. Restaurants in some parts of the world (especially in Asia) have trialed robot waiters: these can be wheeled robots that carry trays from the kitchen to tables along fixed paths, or even humanoid-like servers that can (in a limited way) take orders or pour coffee. There are also delivery robots being pilot-tested in cities – small cooler-sized robots on wheels that can autonomously navigate sidewalks to deliver food or packages to customers’ doorsteps. In theme parks or entertainment venues, character robots provide novel attractions (Disney’s research into stunt robots that can perform acrobatics as superhero stand-ins during shows, for example). While many of these customer-facing robots are still gimmicks or trials, they illustrate the potential for robots to handle front-end service tasks. Especially in situations like a pandemic, the appeal of contactless robotic service (e.g., a robot delivering room service in a hotel without human contact) became more apparent.

- Agriculture and Outdoors: Agriculture is seeing increasing automation through robotics as well. Large farm machinery has long had autopilot features (GPS-guided tractors), but newer robots can perform more delicate tasks. For instance, robotic lettuce thinners use computer vision to identify sprouts to remove and precisely spray or hoe them. Autonomous orchard vehicles can patrol rows of fruit trees, scanning for fruit ripeness or diseases. There are robotic milking stations for dairy farms that allow cows to walk in and be milked by a robotic system on their own schedule. Drone usage in agriculture is widespread for monitoring crop health from above, but ground-based robots are also used for tasks like weeding (using mechanical weeders or targeted micro-spraying of herbicide only on weeds), thus reducing chemical use. Some farms use small rover robots to pick strawberries or harvest other delicate fruits which traditionally are very labor-intensive to gather. By working day and night and optimizing resource use, agricultural robots promise to improve yields and reduce the need for manual farm labor, which is increasingly in short supply in many regions.

- Education and Research: Robots have found a role as educational tools themselves. Educational robot kits (like LEGO Mindstorms or VEX robots) are used to teach students STEM concepts and programming through hands-on building and coding. Beyond kits, some classrooms have simple humanoid robots that help engage children in learning activities – for example, a robot that teaches basic language skills by interacting with students. In research contexts, robots are commonly used as experimental platforms to test AI algorithms, human cognition (by studying how people react to robot behavior), and even social sciences questions. For instance, humanoid robots are used in psychology experiments to see how humans attribute personality or mind to machines. Robotic simulations and competitions (such as FIRST Robotics or university robotics contests) spur innovation and skill development.

In sum, the applications of robots span nearly every field where automation, precision, or the ability to operate in hazardous environments is beneficial. From speeding up industrial productivity to exploring other planets, from helping surgeons to assisting customers, robots have become versatile tools. The continuous improvements in sensors, artificial intelligence, and mechanical design are enabling robots to take on new tasks that were previously difficult to automate. As robot costs come down and user interfaces improve, we can expect their application to broaden further, including into small businesses and personal use scenarios that are currently just emerging.

Future of Robots

The future of robotics points toward machines that are more intelligent, more ubiquitous, and more closely integrated into the fabric of everyday life and work. Several key trends and developments are shaping what robots of the coming decades will be like:

- Advanced Artificial Intelligence and Autonomy: One clear trajectory is that robots will become smarter and more autonomous as AI technology progresses. This means moving from today’s mostly pre-programmed robots to machines that can understand complex environments, learn new tasks on their own, and adapt to unforeseen situations in real time. Modern AI, particularly machine learning and computer vision, is enabling robots to recognize objects, navigate with minimal prior mapping, and even interact socially (to a limited extent). A major goal is to transition from rule-based automation to goal-based autonomy. Instead of scripting every motion, future robots might be given high-level goals and figure out the steps to achieve them, much as AI systems are trained in simulation. For example, a household robot might be told “clean the house” and it will determine how best to vacuum, dust, and organize items by itself, reasoning out a plan and adjusting if it finds, say, an unexpected spill. Recent breakthroughs in AI – such as deep learning for vision and language, as well as techniques from reinforcement learning – are being integrated into robotics. One striking example was OpenAI’s experiment where a robot hand learned to manipulate a Rubik’s Cube through intensive training, demonstrating the potential of AI to handle dexterous tasks that were once extremely challenging for robots. We can expect this trend to continue, with robots increasingly able to learn from demonstration or experience rather than requiring explicit programming for each new job.

- Proliferation of Service Robots and Cobots: Industry analysts predict enormous growth in the service robot sector. While industrial robot sales are still significant, the next wave of expansion is expected in service applications – from health care to retail to personal use. According to one projection, by 2030 the market for professional service robots (like medical and logistics robots) could more than double that of traditional industrial robots. Several factors drive this: aging populations in many countries (creating demand for elder care and assistance robots), rising labor costs and shortages for certain jobs, and ongoing technological improvements making robots safer and more affordable to deploy in human-centric environments. Collaborative robots (cobots), which work side by side with humans, represent a significant part of this future. Unlike the big isolated industrial arms, cobots are designed to be aware of and responsive to human co-workers – for instance, automatically pausing if a person gets too close. This makes them suitable for small and medium enterprises and even tasks at home. By blending human flexibility and robot efficiency, collaboration is seen as a model for the workplace of the future. We might have robots as co-workers taking over the most repetitive parts of a job while humans handle the more nuanced decisions. Aging demographics, especially in countries like Japan and across Europe, also mean there will be fewer workers to care for an increasing number of elderly – a gap that assistive robots (for tasks like lifting patients or reminding them to take medication) might partially fill. The COVID-19 pandemic also accelerated interest in service robots that can reduce human contact in infectious situations (e.g., delivery robots, UV disinfectant robots), potentially making such robots more commonplace in public settings.

- Integration with IoT and Cloud Computing: Future robots will not operate as isolated systems but as part of a connected digital ecosystem. The rise of the Internet of Things (IoT) means many objects in our environment (appliances, sensors, vehicles) are becoming “smart” and networked. Robots will tap into these networks to function more effectively – for example, a delivery robot might communicate with smart traffic signals for optimal routing, or a service robot at home might coordinate with a smart fridge to know if groceries are running low. Cloud robotics is an emerging concept where robots offload heavy computation or learning tasks to cloud servers. This way, a robot doesn’t need to carry all the computational power on board; it can query a cloud service for, say, the latest object recognition model, or to update its maps by learning from what other robots have seen. 5G and future communication networks, with their high bandwidth and low latency, will facilitate this connectivity. In industrial settings, this aligns with the idea of Industry 4.0, where machines, robots, and computerized systems are all interconnected in smart factories. Each robot could be constantly updated with collective data from an entire fleet, meaning when one robot learns something, all its “siblings” can benefit – leading to rapid improvements. Companies are also exploring Robot-as-a-Service (RaaS) business models, where instead of purchasing a robotic system, businesses subscribe to robot services much like cloud computing services. In such scenarios, a robotic cleaning service might be booked on demand and the robot could be shared or used in multiple locations, coordinated via cloud software.

- Better Mobility and New Form Factors: Future robots will be much more agile, taking them closer to the mobility of humans and animals. The progress by Boston Dynamics and others suggests that the once notoriously difficult problems like bipedal balance or complex terrain navigation will be largely solved. We could see emergency-response robots that can climb ladders, scramble over rubble, or even run at considerable speeds on rough ground. Enhancements in actuator technology (such as compact motors or artificial muscles) and materials (like lighter, stronger alloys or composites) will improve power-to-weight ratios, enabling robots to be more efficient and carry more. Soft robotics is another promising area – robots made of flexible materials and driven by pneumatics or electroactive polymers. These soft robots can squeeze through tight spaces or handle fragile objects with a delicate touch. Future household robots might incorporate soft grippers to safely handle everything from picking up toys to folding laundry without damaging them. Modular robots are also on the horizon: these are robots that can reconfigure themselves by attaching and detaching modules, thus changing their shape or function on the fly. For example, a set of robotic modules could assemble into a snake-like form to crawl under a door, then reassemble into a wheeled form to move quickly, and perhaps form a manipulator arm to push a button. Research prototypes of such shape-shifting robots exist, and by 2030 we might see practical versions for tasks like space exploration or search-and-rescue where adaptability is crucial.

- Human-Robot Interaction Improvements: As robots move more into public and personal spaces, making them intuitive and safe for people to work with will be paramount. Future robots will have more natural interaction capabilities – improved speech recognition and generation, more human-like expression via face or body language, and the ability to learn social cues. We may see home assistant robots that you can talk to much like you’d talk to a person, with AI so advanced that the conversation flows naturally (building on the current generation of voice assistants, but embodied in a robot that can physically act). Gestural interfaces and maybe even brain-computer interfaces could allow commanding robots without complex programming. Robotics companies are already investing in user-friendly programming, often using demonstration (where you physically guide a robot arm through a motion and it learns that task) or plain-language instructions. This trend will continue to reduce the barrier to deploying and customizing robots. In workplaces, training a robot might become as simple as giving it a few verbal instructions and corrections as it tries a task. Safety is another critical aspect of HRI (human-robot interaction): advancements in sensor technology and AI will let robots predict and avoid human movements to prevent accidents. For instance, a future autonomous car (a kind of robot) will not only detect a pedestrian but anticipate that a child near a road might run into the street after a ball, and slow down preemptively. In factories, tomorrow’s cobots might be physically incapable of exerting dangerous force thanks to smarter motor controls and lighter materials, making near zero-injury work environments a realistic goal.

- Economic and Workplace Transformation: On a societal level, as robots become more capable, they are poised to transform the economy and labor market. By the 2030s, tasks that were once considered too complex for automation may be routinely handled by robots. Analysts estimate that a significant share of current jobs could be affected by automation – one study suggests up to 30% of work hours globally could be automated by 2030 given the current AI and robotics trends. This does not necessarily mean mass unemployment; historically, automation increases productivity and creates new jobs even as it displaces others. The future likely holds a shift in job composition: roles that involve repetitive physical work or basic data processing will shrink, while new roles in robot maintenance, programming, supervision, and in domains that are hard to automate (creative work, complex human care, etc.) will grow. In the near term, robots complement human labor – for instance, exoskeletons might allow an older workforce to remain active by reducing physical strain, and cobots can mitigate worker shortages in jobs like welding or warehouse picking. Over the longer term, some envision an economy where robots handle most routine production and services, potentially leading to greater leisure time for humans or a focus on more creative and interpersonal endeavors. However, this transition demands foresight in education and policy to reskill workers. We may also see economic models adapt, such as through the consideration of a robot tax (which has been debated as a way to offset the societal costs of automation) or other mechanisms to distribute the productivity gains.

- Exponentially Growing Markets and Innovation: The robotics market itself is expected to expand greatly. One indication is investment levels: robotics startups have been attracting substantial funding, and major tech companies (Google, Amazon, Toyota, etc.) are investing heavily in robotics research. Global robotics market size projections vary, but many analysts forecast robust growth – on the order of the market doubling or more in the 2020s. For example, one report estimated the overall robotics market (including software and components) might grow from about $70 billion in 2025 to over $150 billion by 2030. By 2025, worldwide spending on military robotics, autonomous vehicles, and medical robots will also be far higher than today. This influx of resources will accelerate innovation, potentially leading to breakthroughs in long-standing challenges: perhaps achieving human-level hand dexterity, or creating reliable robotic perception that can understand its environment as robustly as a human does.

Looking further ahead, the lines between robots, AI agents, and even biological beings may blur. Experiments in robotic prosthetics and brain-controlled robots hint at a future where humans and robots interface more directly (augmented humans using robotic limbs, or perhaps mind-controlled robot avatars doing work in hazardous environments on behalf of a person safely elsewhere). In manufacturing and goods, the rise of 3D printing (additive manufacturing) could work in tandem with robotics to enable highly automated local production; a robotic factory of the future might print and assemble complex products with minimal human intervention. Swarm robotics might take off, where many simple robots coordinate to accomplish what one large robot cannot – imagine swarms of small construction robots that could assemble buildings with each robot placing one brick at a time in coordination, or a swarm of agricultural bots tending each plant individually in a giant farm.

In summary, the future of robots is poised to be characterized by greater intelligence, collaboration (with humans and with each other), adaptability, and pervasiveness in society. Robots will likely handle more tasks in more environments – not just factories and laboratories, but city streets, hospitals, offices, and homes. This progression offers immense benefits in terms of productivity, safety, and convenience, but also raises new challenges in areas like employment, ethics, and security. How society navigates this future – embracing the benefits of robotics while managing its disruptions – will be a defining aspect of the coming technological era.

Impact on Society

The growing presence of robots has profound implications for society. As robots step out of factories and lab environments into workplaces, public spaces, and homes, they influence how we live and work. The impacts can be examined from multiple angles: economic (jobs and productivity), social (the human experience of working with or being served by robots), and broader societal shifts (skill demands, lifestyle changes, policy and infrastructure needs).

Economic and Labor Impact: Perhaps the most discussed societal impact of robots is on employment and the economy. Robots can automate tasks that were formerly done by people, raising concerns about job displacement. There is clear evidence that industrial robots have already changed manufacturing employment. A study by economists Daron Acemoglu and Pascual Restrepo found that in the U.S., each additional robot per 1,000 workers in a region led to an employment decline and wage reduction in that area; specifically, adding one industrial robot in a commuting zone was associated with about 6 jobs lost in that zone, and overall a 0.2% drop in the employment-to-population ratio nationally. By their estimates, the introduction of industrial robots in the late 20th century accounted for hundreds of thousands of manufacturing job losses and some downward pressure on wages for certain skill groups. These findings underscore that robots can replace certain tasks especially in routine, manual jobs. Workers in roles like assembly line operations, welding, or packaging have in some cases been directly substituted by robotic systems. This has contributed to the decline of some middle-skill jobs, a factor in observed polarization of the labor market (where high-skill and low-skill jobs grow, but mid-skill jobs shrink).

However, the economic impact of robots is not simply one of job destruction – it is more nuanced. Robots also create jobs and raise productivity, which can lead to economic growth and new employment opportunities. Firstly, the robotics industry itself generates jobs (designing, building, programming, maintaining robots). More importantly, by taking over low-value or dangerous tasks, robots can make businesses more efficient and competitive, potentially leading to expansion and hiring in other areas. The International Federation of Robotics argues that “robots increase productivity and competitiveness… the net impact on jobs and the quality of work is positive” when one considers how automation can lead to business growth and the creation of new roles. Historical analogies are often drawn to past automation like agricultural machinery or computers – while those technologies displaced some occupations, they ultimately boosted economies and created entirely new job categories. For example, as automotive robots took over repetitive work, more jobs opened in robotics engineering, programming, systems integration, and in higher-skilled production roles. Additionally, productivity gains from robots can lower production costs and prices of goods, increasing demand and potentially creating jobs in supply chains and distribution (this effect is known as the productivity or output expansion effect). One study of 17 advanced economies estimated that robot adoption between 1993 and 2007 contributed about 10% of total GDP growth in those countries and also a measurable increase in labor productivity. In other words, robots have been likened to past general-purpose technologies like the steam engine in terms of their positive contribution to economic growth.

The true labor impact lies in task reallocation: robots substitute for certain tasks within jobs, not entire jobs wholesale (in most cases). It’s often said that less than 10% of occupations are fully automatable, but a much larger percentage have a substantial portion of tasks that could be done by machines. For instance, in a warehouse, robots might handle the transporting of goods within the facility (a major part of a worker’s routine), but human workers still do tasks requiring judgment or complex dexterity, like packing a delicate custom order. This means that many jobs will evolve rather than vanish: humans will focus on the aspects that machines can’t (yet) do, which often are the more cognitive or people-oriented aspects. An assembly line worker might transition to overseeing a set of robotic machines, becoming a maintenance technician or quality controller rather than doing the wrench-turning manually. New skills and roles are in demand – robotics technicians, AI specialists, automation supervisors, etc. The societal challenge is ensuring the workforce is reskilled to fill these new positions. There is concern that without adequate training programs, some workers displaced from routine jobs may struggle to find new employment, leading to structural unemployment or widening inequality between high-skill and low-skill workers. Indeed, higher-skilled workers (especially those with college degrees) tend to benefit from complementing robots (they design or manage automated systems), whereas lower-skilled routine workers face more competition from robots. Education systems and vocational training are increasingly focusing on STEM, programming, and technical maintenance skills to prepare upcoming generations for working alongside robotics.

It’s also important to note that job quality can improve with robots. By assigning machines the “3 D’s” – jobs that are dull, dirty, or dangerous – workers are relieved from hazardous or mind-numbing duties and can be allocated to more engaging tasks. For example, in mining, automated haulage trucks mean fewer drivers have to work in dusty, perilous open pits; in manufacturing, robots painting car bodies protect workers from toxic fumes. This can lead to safer workplaces and reduce occupational health issues. Some economists argue that rather than simply eliminating jobs, robots “complement and augment labor” – taking over parts of a job and thus acting as a tool that allows a human worker to be more productive. A human-robot team might accomplish far more than either alone, which can justify higher wages for the human due to higher productivity. Indeed, countries that are leaders in robotics adoption (like South Korea, Germany, Japan) often have low unemployment and strong manufacturing sectors – indicating that high automation can coexist with a strong labor market, provided the economy transitions the workforce effectively.

The debate on robots and jobs is ongoing. Some fear a scenario where automation outpaces the creation of new work, leading to technological unemployment at an unprecedented scale. Others point to historical resilience of labor markets and argue new human roles will emerge (for instance, jobs we can’t even imagine today, much as software development was a niche job 50 years ago and is huge now). What is clear is that society must manage the transition. Policies under discussion include stronger social safety nets for displaced workers, government and industry investment in retraining programs, and possibly new economic measures like a universal basic income if automation significantly reduces the need for human labor in aggregate. As of a 2024 report, the World Economic Forum predicted that while around 85 million jobs may be displaced by automation by 2025, about 97 million new jobs could be created in fields related to AI and robotics – a net positive, but contingent on workers having the skills to fill those new jobs. Managing inequality is a concern: if robotics leads to productivity gains that mainly accrue to robot owners or highly skilled engineers, the wealth gap could widen. Tax and redistributive policies may need to adapt – for example, there was a high-profile proposal by Bill Gates to tax robots (the idea being that companies replacing workers with robots should pay equivalent payroll taxes) to fund retraining, though as of now this has not been implemented and is opposed by industry groups as potentially stifling innovation.

Social and Lifestyle Impact: Beyond economics, robots in society affect daily life and human interaction. As more people encounter robots in workplaces, stores, or homes, societal attitudes and norms evolve. Initially, there can be fear or resistance – the notion of “robots taking over” has been a science-fiction trope and a public anxiety for decades. However, familiarity often breeds comfort. In Japan, where service robots and robot pets have been experimented with widely, many older adults have grown accustomed to robotic caregivers or companions, sometimes expressing affection towards devices like robotic seal pets used in therapy. The introduction of robots can change social behaviors: for example, pedestrians might adapt their behavior when they see a delivery robot on the sidewalk, just as they would for a person or pet, eventually treating it as a normal part of the environment.

Robots also raise questions of human connection and behavior. If robots handle more customer service, will human interaction decrease in some domains? Some restaurants with tablet ordering or robot waiters may offer efficiency but at the cost of the friendly conversation with a waiter. In healthcare or caregiving, substituting human caregivers with robots (even partially) might lead to reduced human contact for vulnerable people, which could impact emotional well-being. On the other hand, if designed right, robots can provide companionship and reduce loneliness – e.g., socially assistive robots can encourage patients to do their physical therapy exercises or remind dementia patients of daily routines with infinite patience, something caregivers might struggle to maintain constantly. The net effect on care and empathy in society will depend on how we integrate robots: ideally, robots should free up time for humans to spend on truly social and interpersonal aspects of care, rather than replacing those aspects.

The presence of robots can also influence human behavior via something known as the Hawthorne effect – people may change how they work when they know a robot (or algorithm) is monitoring them. In warehouses where robot systems track worker performance, employees might feel increased stress or push to keep pace with the machine. The dynamic of working “under supervision” of algorithms is a new psychosocial aspect of workplaces. Labor regulators and organizations are paying attention to how to ensure humane working conditions in such settings (for instance, making sure workers can take breaks even if the automated system optimizes for constant throughput).

Another social question is how we perceive robots – do we treat them as tools, or begin to treat them as a kind of new entity in our society? Already, experiments have shown people often name their robot vacuum cleaners or feel “bad” for a robot that appears to get stuck or “hurt.” As robots become more anthropomorphic or zoomorphic (animal-like), humans are prone to projecting emotions onto them. This can be used positively (therapeutic robots leveraging our empathy), but also raises ethical questions (is it deceptive to design a robot to appear caring when it’s just a machine following a program?). The concept of robot rights has even been speculated: if future AI-driven robots attain a form of sentience or at least sophisticated autonomous behavior, some argue they might deserve a form of moral consideration. While that remains a hypothetical scenario for now, it challenges our definitions of life and agency.

Education and Skills: Society will likely place a premium on education in this robotic age. STEM education – science, technology, engineering, math – is emphasized by many governments to prepare youth for a high-tech economy. But equally important may be creativity, critical thinking, and interpersonal skills – these are areas where humans maintain an edge and which complement robotic automation. We might see more interdisciplinary training (for example, nurses learning to operate and troubleshoot assistive robots, or plumbers learning to fix household service robots). Lifelong learning will become a norm, as workers may need to update their skills multiple times as technology evolves. Robots might ironically become partners in education themselves, as tutors or educational tools, helping humans learn new skills in personalized ways.

Daily Convenience and Lifestyle: On the individual level, robots could bring significant convenience. Tasks like cleaning, driving, grocery shopping (with delivery robots or drones), and other chores might largely be offloaded to robots, potentially giving people more free time or allowing those with disabilities to live more independently. Homes of the future might each have a suite of domestic robots handling routine tasks. Personal transportation could be transformed by autonomous cars, freeing people from driving and reducing accidents (with implications on everything from commuting patterns to urban design, since parking needs might decrease if cars can auto-relocate or be shared). These changes can improve quality of life, but they also require adaptation: e.g., city infrastructure adjusted for autonomous vehicles, new traffic laws, insurance models, etc.

There is also a geopolitical and inequality dimension: advanced robots are expensive and require technical infrastructure. Without proper measures, their benefits might concentrate in wealthy companies or countries, potentially widening global inequalities. Developing countries that currently rely on labor-cost advantages in manufacturing could see industries shrink if robots allow reshoring of manufacturing to high-wage countries (since labor cost matters less when production is automated). Indeed, increased robot use has enabled some firms in high-income countries to “reshore” manufacturing that had moved abroad for cheap labor. This could impact emerging economies’ development paths. On the positive side, affordable robots (especially open-source designs or low-cost models) might become available and boost productivity even in smaller enterprises globally, much as mobile phones leapfrogged communications in developing nations. International organizations and policymakers are looking at how to ensure access to AI and robotics so that benefits are broadly shared, rather than exacerbating a digital divide.

Psychological Impact: Interacting with robots might subtly change human psychology. Some worry about humans losing certain skills (for instance, navigation skills might decline if we rely solely on robot drivers or GPS; manual crafting skills might fade if everything is automated). There’s also the potential for dependency on robotic help – e.g., children who grow up with AI assistants might become accustomed to immediate answers and less inclined to memorize information or learn certain effortful tasks. Conversely, robots could also enhance cognitive abilities (like providing on-demand coaching or memory aids) and help people achieve more than before.

In workplaces, the role of human labor will shift more towards oversight, exception handling, and creative problem-solving – which could make many jobs more fulfilling if handled right, or more monotonous if the human is just watching machines work. Companies will need to consider job redesign to ensure humans remain engaged and not simply bored “monitor operators.”

The integration of robots also raises questions of identity and dignity. Many people derive pride and identity from their work. If a machine takes over tasks that gave a worker their sense of purpose, there could be a psychological toll. It will be important for societies to value human contributions that are not easily automatable – such as artistic, caregiving, and community roles – and perhaps redefine how we esteem various activities (for example, increased respect and reward for jobs that robots cannot do, like creative arts or highly empathetic professions).

In summary, the societal impact of robots is double-edged: significant economic benefits and potential improvements in safety and quality of life, coupled with disruption to existing job structures and human routines. Navigating this will require proactive adaptation: educational reforms for the workforce, social policies to mitigate inequality and assist displaced workers, and cultural evolution to embrace working alongside intelligent machines. Just as previous technological revolutions ultimately raised living standards while forcing social change, the robot revolution promises a more efficient and potentially prosperous society – if the challenges are managed with foresight and care.

Impact on Technology

Robotics is not only shaped by technological progress; it is itself a driver of new technologies and innovations. The demands of building better robots have spurred advances in multiple fields of science and engineering, while the widespread adoption of robots is influencing technology standards and infrastructure.

Accelerating Hardware and Software Development: The quest to make robots more capable pushes the frontiers of hardware development. For instance, consider sensors: Robots need to perceive their environment accurately, which has led to rapid improvements in camera technology (high-resolution, high-dynamic-range, and depth-sensing cameras like the Microsoft Kinect were partly driven by robotics and gaming needs), LiDAR sensors for 3D mapping (popularized by autonomous vehicles, now becoming smaller and cheaper), ultrasonic and tactile sensors, and more. Similarly, actuators and motors have seen innovation. Roboticists demand motors that are powerful yet lightweight, and responsive yet energy-efficient. This has led to improved electric motor designs, compact gearboxes, and even explorations of artificial muscle materials (like electroactive polymers or shape-memory alloys) that could provide more organic, flexible motion. The field of battery technology is also influenced by robotics – mobile robots and drones require dense energy sources to run longer. Efforts to improve battery energy density (in lithium-ion and beyond) benefit from the growing market of autonomous cars and drones, which in turn will benefit all portable electronics and electric vehicles. Inverse, some robotics teams are exploring alternatives to batteries, such as energy harvesting for small robots or tethered power for certain applications, which influences how power electronics are designed.

On the software side, robotics presents some of the hardest challenges in AI and computing, thus driving progress there. For example, the need for real-time image recognition and decision-making in robots helped motivate the development of specialized AI chips (GPUs and newer AI accelerators) that can process neural networks quickly on the edge. Companies like NVIDIA have seen a synergy between the needs of robotics and their graphics/AI processors. The development of algorithms for SLAM (simultaneous localization and mapping) in robotics has cross-pollinated into technologies for augmented reality and autonomous driving. In general, robotics promotes the field of real-time computing – creating systems that can respond within microseconds or milliseconds reliably. This has led to enhancements in operating systems (like the development of the ROS – Robot Operating System – which is a middleware facilitating robotics software development) and improved real-time extensions for common OS, benefitting industries like automation and aerospace.

Robotics also stress-tests telecommunications – for teleoperated robots or cloud-connected robots, you need stable, low-latency communication. This has provided use cases that push 5G deployment (one use case touted for 5G is remote surgery with surgical robots, requiring minimal latency to ensure the surgeon’s motions are faithfully reproduced miles away). So, telecom companies have incentives to reduce latency and improve reliability partially because such high-stakes robotic applications are on the horizon.

Interdisciplinary Innovation: Robotics sits at the crossroads of many disciplines: mechanical engineering, electrical engineering, computer science, AI, materials science, control theory, neuroscience, even biology. This interdisciplinary nature means advancements in one domain can rapidly be incorporated into robotics. Conversely, challenges faced in robotics force interdisciplinary collaboration that yields novel solutions. For example, in trying to replicate animal locomotion, roboticists have worked with biologists – leading to new insights in both fields (bio-inspired robots on one side, and on the other, using robots to test biological hypotheses about movement). The field of prosthetics and bionics is a clear case where robotics (mechanisms, sensors, actuators) meets neuroscience (nerve signals, brain-machine interfaces) to create artificial limbs controlled by the mind. Progress here not only gives amputees more functional limbs but also furthers understanding in neural engineering and muscle signaling.

Feedback to AI Research: Real-world robotics provides a testing ground for artificial intelligence algorithms outside of simulated or purely digital contexts. An AI algorithm that plays chess or labels photos faces a very static, rule-bound problem; but a robot dealing with the unpredictability of the physical world forces AI to handle incomplete information, noise, and unforeseen events. Robotics thus drives research into robust AI and adaptive learning. Concepts like reinforcement learning (where an AI learns by trial and error, receiving feedback rewards) have been advanced substantially with robotic challenges in mind, such as teaching a robot hand to manipulate objects. Also, integrating AI into hardware raises new issues like safety (ensuring an AI action doesn’t cause harmful physical behavior) and verification (proving that a robot will operate within certain bounds), pushing computer science research in those directions.

Standards and Modularity: As robotics deployment increases, it’s influencing technology standards. Efforts are underway (by groups like IEEE and ISO) to standardize aspects of robotics – for safety, for communication protocols, for performance metrics. For example, ISO has standards for collaborative robot safety and for service robot terminology. These standards then inform the design of sensors and interfaces. One impact is modularity and compatibility: manufacturers of robot components are moving toward more plug-and-play designs. A company making a robotic gripper might follow standard interfaces so that their gripper can attach to any compliant robot arm, just as USB became a standard for peripherals in computing. This modular approach can accelerate innovation by allowing different companies to specialize (one makes great vision systems, another makes great robotic arms, and a user can combine them easily). It also introduces ecosystems of components, akin to an app store model but for hardware and software modules that work together. As this matures, building a custom robot for a new task could become a matter of selecting modules rather than designing everything from scratch.

Influence on Digital Infrastructure: When many robots come into use, especially mobile ones like autonomous cars or drones, they become a part of the infrastructure conversation. Cities might incorporate sensors on roads to assist self-driving cars, or dedicate lanes for delivery robots. Air traffic control systems might expand to manage autonomous drones delivering packages. All these require technological infrastructure upgrades: ubiquitous connectivity (cities installing 5G small cells for constant coverage), digital traffic management systems, and even smart city grids where traffic lights communicate with autonomous vehicles. In warehouses and factories, the layout of facilities is now often designed with robots in mind, including QR codes on floors or ceilings for robot navigation, or retrofitting old warehouses with wireless networks and charging stations for fleets of warehouse robots. This further blurs the line between the digital and physical – infrastructure itself is becoming robot-friendly and often robot-managed (like automatic recharging stations that robots use without human help).

New Technology Adoption and Consumer Expectations: The presence of robots can drive general adoption of related technologies. For instance, when people get used to interacting with a robot via voice or touch, they may expect similar interfaces elsewhere. The popularity of voice-activated assistants was partly eased by experiences with things like Siri or Alexa; similarly, interacting with a service robot at a hotel lobby might make someone more comfortable using AI chatbots on websites. Robotics can thus act as ambassadors for AI technology to the public, normalizing things like natural language processing and face recognition in everyday life. This can accelerate consumer acceptance and demand for smart devices overall. It can also push regulatory frameworks – for example, if delivery drones become common, that accelerates the need for drone traffic rules and maybe the development of quieter drone propulsion tech to address noise concerns.